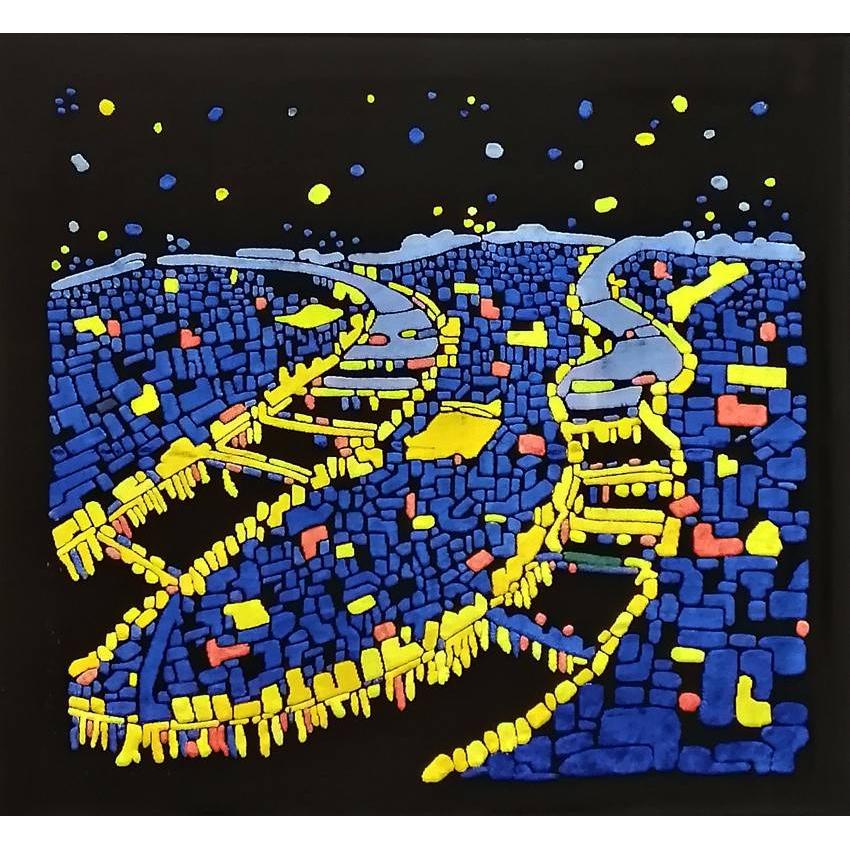

Benito - Lyon Heritage 1998

Availability: 0 remaining

The “Made in Lyon and its surroundings” label promotes products manufactured within a 20 km radius, reflecting traditional Lyonnais know-how.

Technical data

| Size | 105 x 115cm |

| Color | Original |

| Composition | Silk and viscose |

| Weaving | Jacquard shaped velvet |

| Made in | Lyon, France |

| Gender | Women |

All our velvet panne scarves are produced in very small series and they are all hand painted, so each piece is unique. IF THE COLOR IS NOT SPECIFIED in the product name, it is advisable to contact us before ordering, we can send you photos of the colors available at the moment.

The long history of Lyon, founded by the Romans as the capital of the Three Gauls in the 1st century BC and which has continued to play a major role in the political, cultural and economic development of Europe since that time, is illustrated in an extremely vivid manner by its urban fabric and by many historic buildings from all periods. On December 5, 1998, the historic site of Lyon, an area delimited by the city's ancient fortifications including the Fourvière hill and a large part of the Presqu'Ile, was listed as a UNESCO World Heritage Site. This scarf was published on this occasion by Brochier for Brochier for the Lyon Chamber of Commerce.

MANUFACTURING

Two parallel sheets of silk muslin are connected by a viscose (wood cellulose) warp fed by 1064 bobbins.

Velvet is created by razor-cutting the viscose threads and separating the two layers of silk muslin. The incomparable moiré or shine is obtained by pannage of the velvet which is laid down and brushed with a steam roller. These first steps are carried out in our weaving workshops in the Loire.

After weaving, shaving and pannage, the two-tone piece (black muslin background and white viscose pattern), which measures on average 30 meters (which makes it possible to obtain around twenty shawls) arrives in our finishing workshop on rue Romarin in Lyon, to be colored. The coloring of the white velvet is done in an artisanal way by hand and with a brush, which means that each piece is unique.

Last operation: fixing the colors. This is obtained by steaming, which guarantees the definitive permanence of the shade.

It is in the sewing workshop near Lyon that this marvelous, long and precise work is completed by creating a satin stitch finish.